At Fluid Metering, Inc. we have been dedicated to providing our customers with the highest quality valveless metering pumps, and the best service for over 55 years. Our metering pumps and dispensers are the industry standard for accuracy, precision, and durability, and are used for numerous applications in many industries. To provide the best service for our customers we have created numerous videos that show how our products work, as well as offer technical support to assist you with any issues you may have. Below are some examples.

Fluid Metering Technology Videos

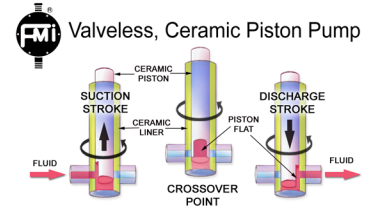

This video is a 3D animation of how our valveless metering pumps work. It shows the design and the components of the pump including the fact that it contains only one moving part which accomplishes all fluid control functions. The video also highlights the sapphire-hard ceramic internals which are wear resistant and chemically inert.

The above video highlights the unique “One Pump Does It All” ability of our FMI CeramPump®. This technology is the solution to a variety of fluid control requirements including aspirating, dispensing, and continuous metering. Useful in applications including hydroponic farming and the medical and laboratory science fields, this pump will improve your accuracy and efficiency.

Precision is very important when it comes to metering pumps and dispensers. Our products offer a high degree of accuracy for use in a wide range of medical, laboratory, analytical and industrial process applications. In the above video we show an actual precision test that proves that Fluid Metering Technology is the best on the market.

Making sure the proper safety precautions are taken when operating a pump is essential. In the above video our Fluid Metering Team member offers some safety precaution tips. These include some of the safety clothing that should be worn and the checking of the MSDS manual for chemical information for the chemicals that will be used in the pump.

Tech Support Videos

Along with the above videos, the Fluid Metering Inc. website includes a section of tech support videos which demonstrate how to install a FMI pump head, how to replace piston pump lip seals, and how to identify the pumps serial number. Our goal is to provide the best support for our customers, and along with these videos we also offer Live Chat Support for a direct connection to Fluid Metering’s experts. For more information on how our products can meet your requirements please contact us.

You must be logged in to post a comment.