Most people know that plants are grown in soil to take full advantage of the nutrients available. In some climates this is not possible, so alternative farming methods had to be created. Hydroponics is a method of growing plants in a water based, nutrient rich solution that does not use soil. Instead the root system is supported using an inert medium such as perlite, rockwool, clay pellets, peat moss or vermiculite. A constant flow of water must be delivered to the roots in this system and pumps are needed to accomplish this.

Crystallization Issues

The proprietary nutrient formulations used by hydroponic farmers contain a variety of minerals that tend to crystallize. This can create problems in metering pump technologies that rely on check valves or flexible peristaltic tubing. Crystallization would eventually cause the check valves to fail and the hardened crystals would cause the elastomer tubing to break down. This would prevent vital nutrients reaching the plants which many times are unattended for several weeks at a time.

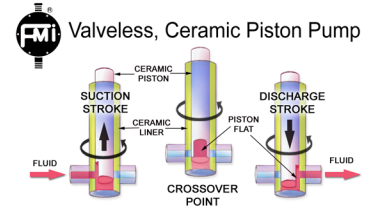

Valveless Pump Solution

The CeramPump Valveless Piston Pump from Fluid Metering, Inc. meets all the needs of the hydroponic farming industry. It utilizes only one moving part in the fluid path which accomplishes both the pumping and valving functions, which eliminates check valves and the associated reliability and maintenance concerns. The CeramPump also has internal components made of sapphire-hard ceramics which are chemical inert, dimensionally-stable and abrasion-resistant which limits the chance of pump failure. To make sure that fluid crystallization is not an issue; the CeramPump is also available with a special wash gland feature which essentially isolates crystal forming fluids from the atmosphere.

FMI’s CeramPump has been successfully used in hydroponic farming for the growing of endives, which are grown unattended for 21 days in the dark. Also flowering plants grown from bulbs are an additional area where FMI’s Valveless Piston pump can deliver nutrient and mineral enriched formulations accurately and maintenance free, even when left unattended for extended periods of time.

For more information on how FMI’s valveless metering pump technology can meet your hydroponic needs, please reach out to product specialist’s here.

You must be logged in to post a comment.